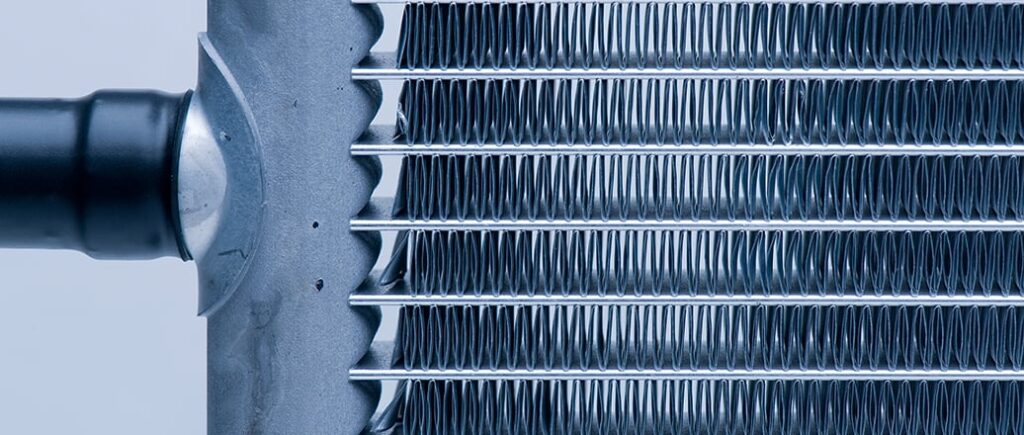

Microchannel heat exchangers (MCHEs) have transformed the landscape of thermal management across various industries, thanks to their enhanced efficiency and compact design. One of the crucial factors contributing to their superior performance is the selection of materials used in their construction. This article delves into the materials commonly used in microchannel heat exchanger and explains why these materials are chosen for their specific properties and benefits.

Aluminum: The Backbone of Microchannel Heat Exchangers

Aluminum is the primary material used in the construction of microchannel heat exchangers. Its widespread use is attributed to several key properties that make it ideal for this application:

- Excellent Thermal Conductivity: Aluminum has high thermal conductivity, which allows for efficient heat transfer. This property is essential for the effectiveness of MCHEs, as it ensures rapid heat dissipation from the refrigerant to the surrounding air.

- Corrosion Resistance: In HVAC and industrial applications, components are often exposed to moisture and varying environmental conditions. Aluminum’s natural corrosion resistance ensures longevity and reliability, reducing maintenance requirements and prolonging the lifespan of the heat exchanger.

- Lightweight: Aluminum is significantly lighter than other metals like copper and steel. This lightweight nature is particularly advantageous in applications where weight is a critical factor, such as in automotive and aerospace industries. It also facilitates easier handling and installation.

- Malleability and Machinability: Aluminum is easy to work with, allowing manufacturers to create the intricate designs required for microchannels. This malleability enables the production of flat tubes with small channels that are essential for maximizing the surface area for heat exchange.

Copper: An Alternative Material

While aluminum is the predominant material for microchannel heat exchangers, copper is sometimes used as an alternative. Copper’s use is driven by its own set of advantages:

- Higher Thermal Conductivity: Copper has an even higher thermal conductivity than aluminum, which can enhance the heat transfer efficiency of the heat exchanger.

- Antimicrobial Properties: Copper possesses natural antimicrobial properties, making it suitable for applications where hygiene is critical, such as in medical equipment and food processing industries.

However, copper is heavier and more expensive than aluminum, which can limit its use in certain applications where cost and weight are significant considerations.

Composite Materials: Innovations in Microchannel Heat Exchangers

Recent advancements in materials science have led to the development of composite materials that combine the strengths of different substances. In the context of microchannel heat exchangers, composites can offer a blend of properties that enhance performance and durability.

- Aluminum Composites: By combining aluminum with other materials, manufacturers can improve specific properties such as strength, corrosion resistance, and thermal conductivity. For instance, adding silicon to aluminum can enhance its hardness and reduce the risk of wear and tear.

- Polymer Composites: Polymers reinforced with fibers, such as carbon fiber or glass fiber, can be used to create lightweight and strong components. These materials are particularly useful in applications requiring high strength-to-weight ratios, such as in aerospace and high-performance automotive industries.

Surface Treatments and Coatings

To further enhance the performance and durability of microchannel heat exchangers, surface treatments and coatings are often applied. These treatments provide additional benefits, such as increased corrosion resistance and improved heat transfer efficiency.

- Anodizing: This electrochemical process increases the thickness of the natural oxide layer on aluminum, providing enhanced corrosion resistance and surface hardness. Anodized aluminum is commonly used in harsh environmental conditions to ensure long-term durability.

- Epoxy Coatings: Applying an epoxy coating to the surface of microchannel heat exchangers can protect against chemical corrosion and physical damage. These coatings are particularly useful in industrial environments where exposure to harsh chemicals is common.

- Hydrophilic Coatings: These coatings improve the wettability of the heat exchanger surface, enhancing heat transfer efficiency by promoting better refrigerant flow and reducing the accumulation of water droplets. This is especially beneficial in HVAC systems where condensation can affect performance.

Conclusion

The materials used in microchannel heat exchangers are integral to their performance, efficiency, and durability. Aluminum, with its excellent thermal conductivity, corrosion resistance, and lightweight properties, remains the material of choice for most MCHE applications. Copper, though used less frequently, offers superior thermal conductivity and antimicrobial properties. Advances in composite materials and surface treatments further enhance the capabilities of microchannel heat exchangers, making them suitable for a wide range of demanding applications. Understanding the properties and benefits of these materials helps in appreciating the technological innovations that drive the efficiency and reliability of modern thermal management systems.